Projects

Russia – Nuclear Power Plant Novovoronezh

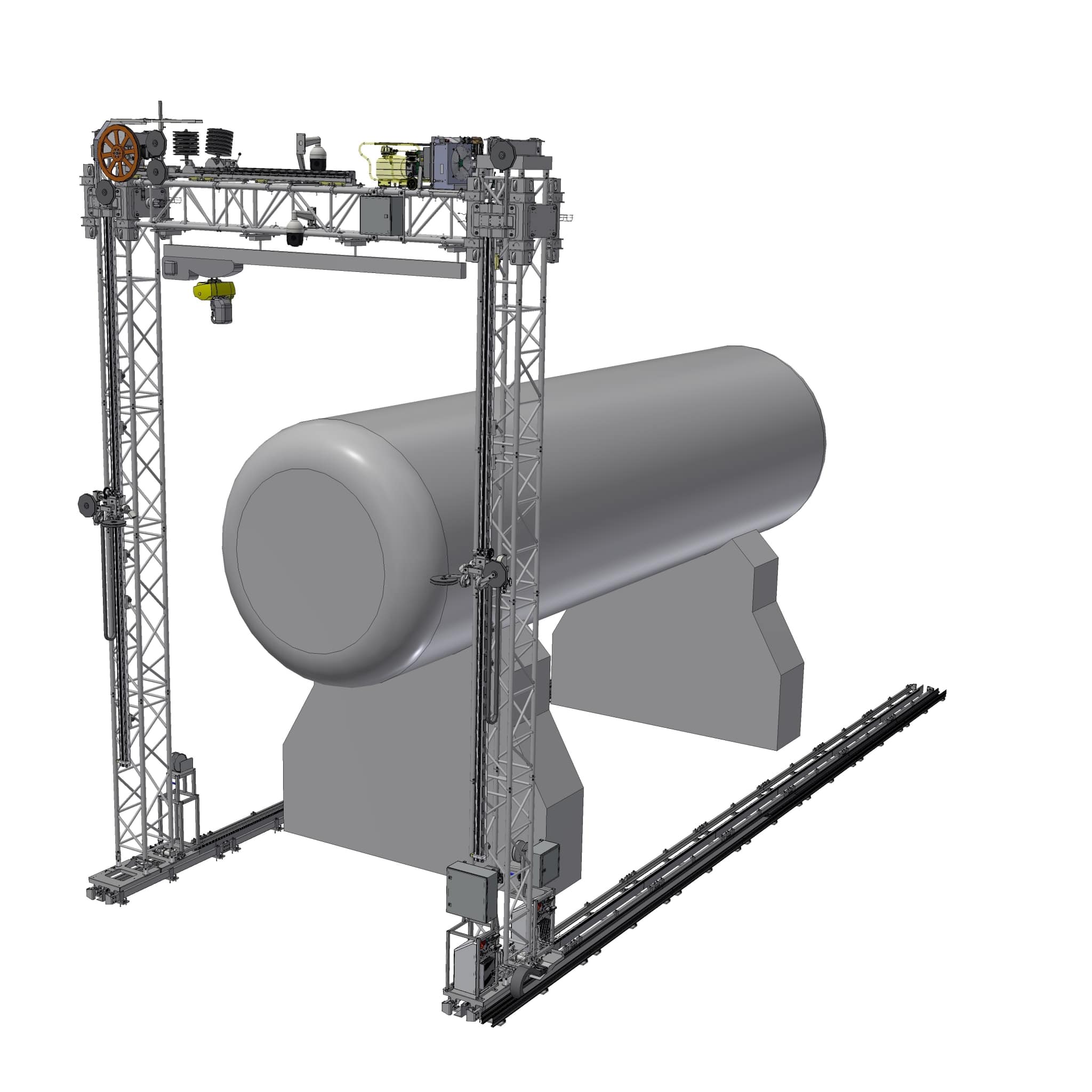

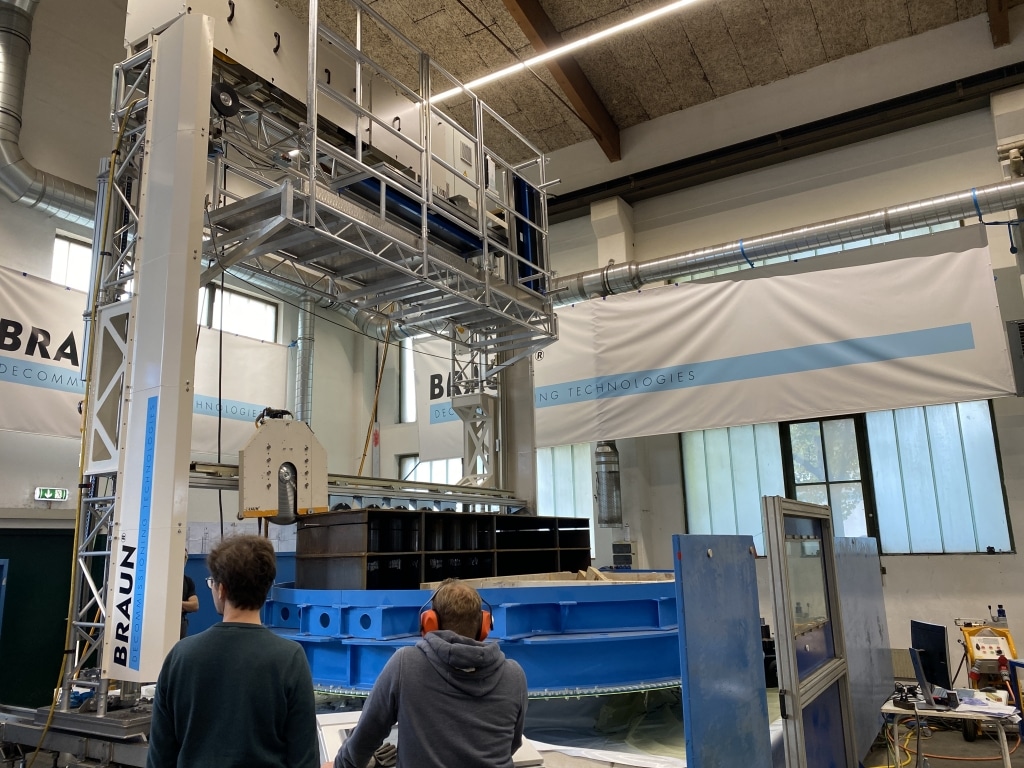

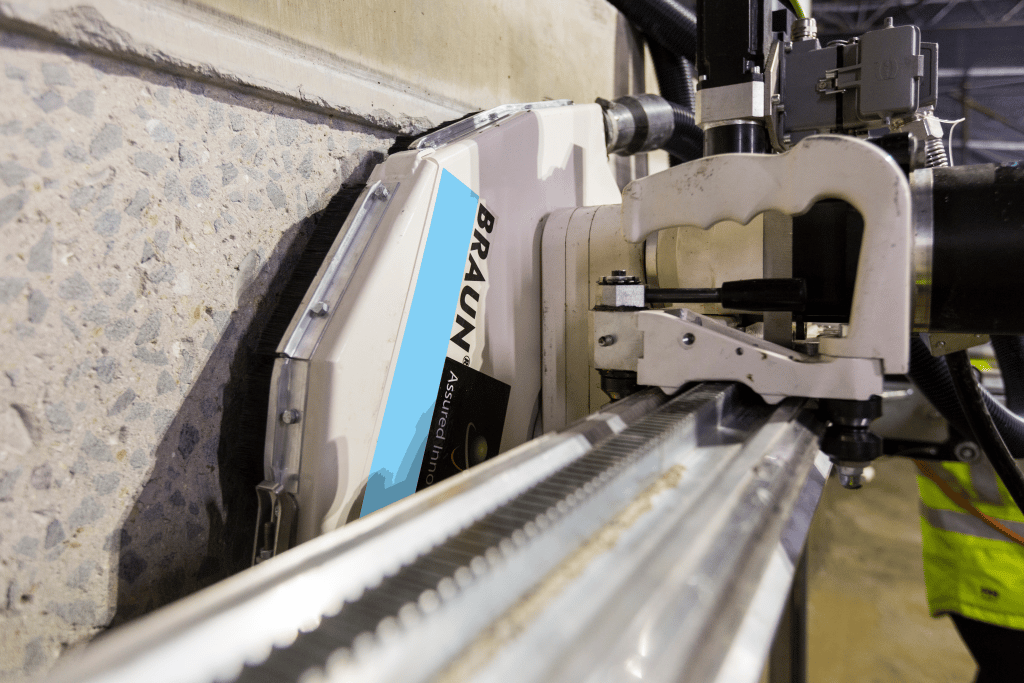

Mobile bridge saw for the dismantling of heat exchangers and also deployed as a post-cutting station to cut disassembled components such as turbines, pumps or pipelines – cooperation with VIP-SYSTEMY.

task and problem definition

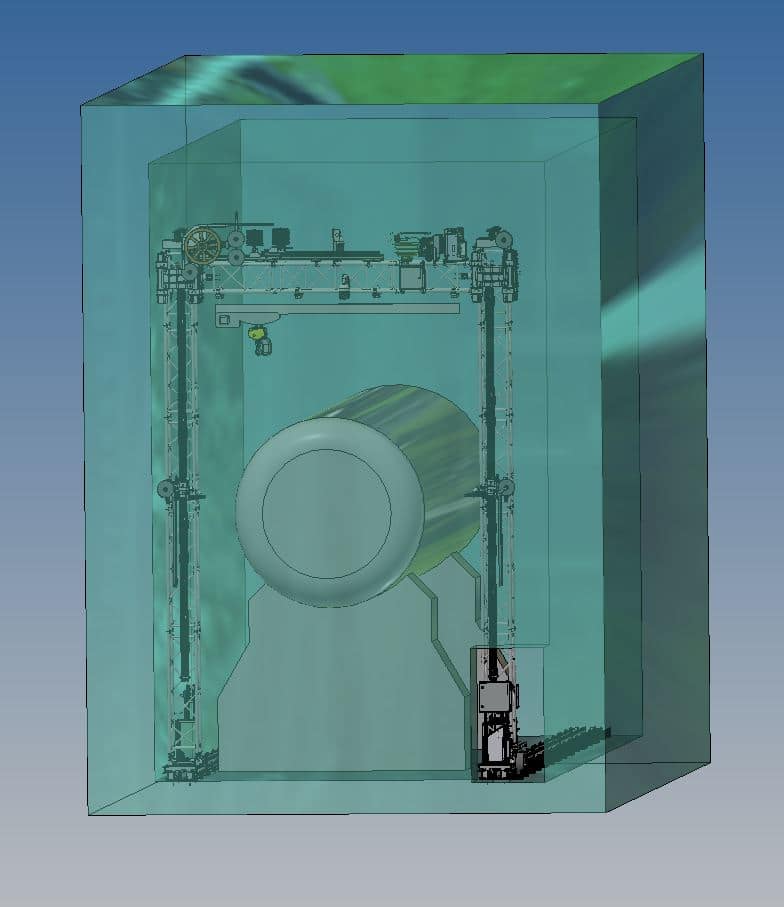

Transport of the machine through a normal door

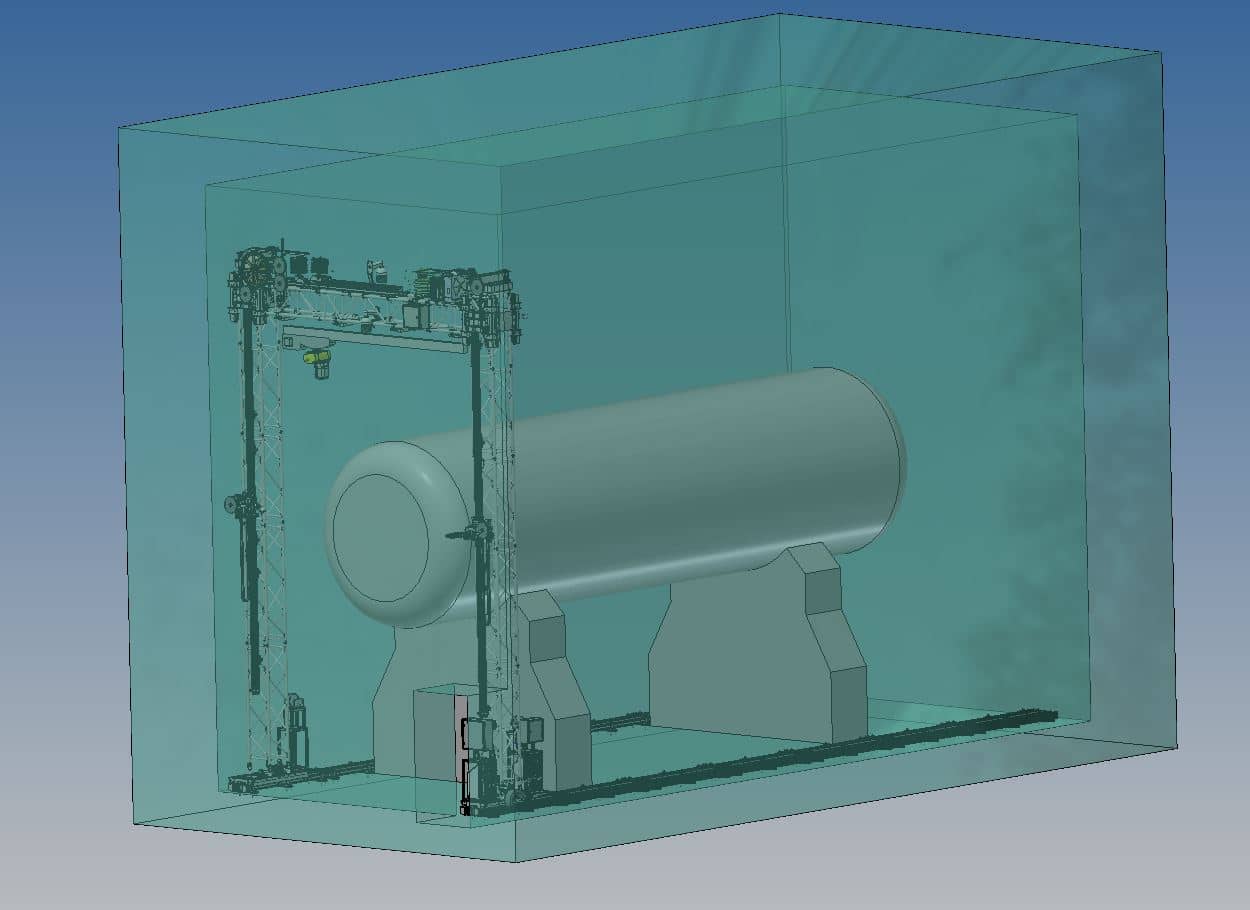

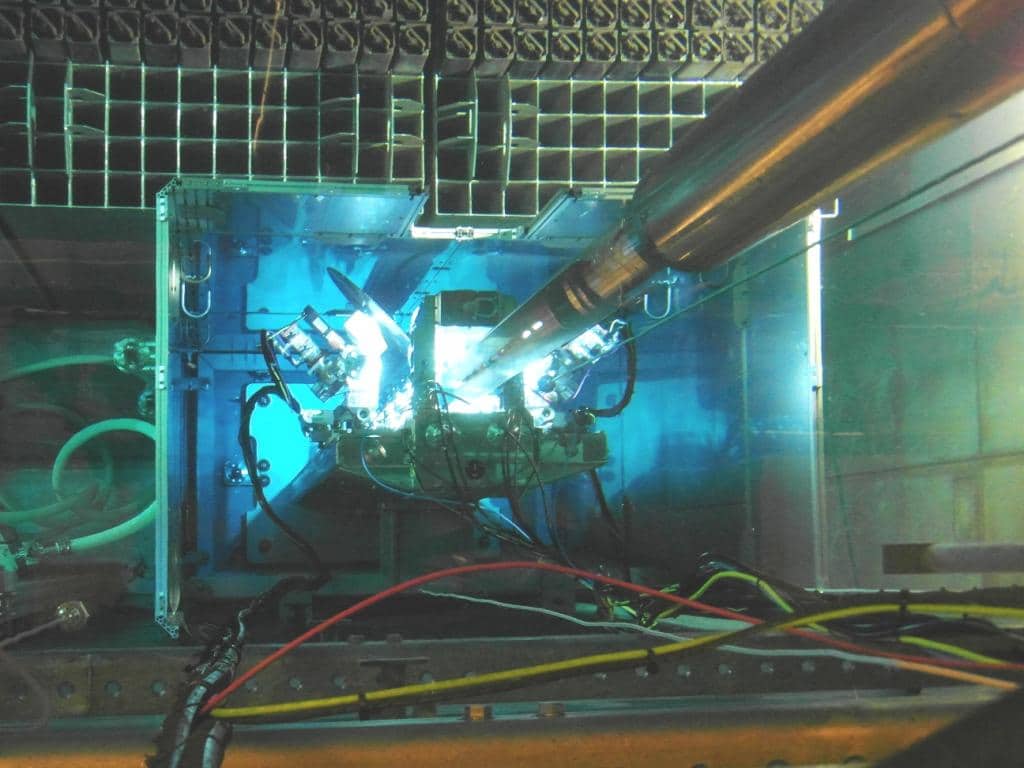

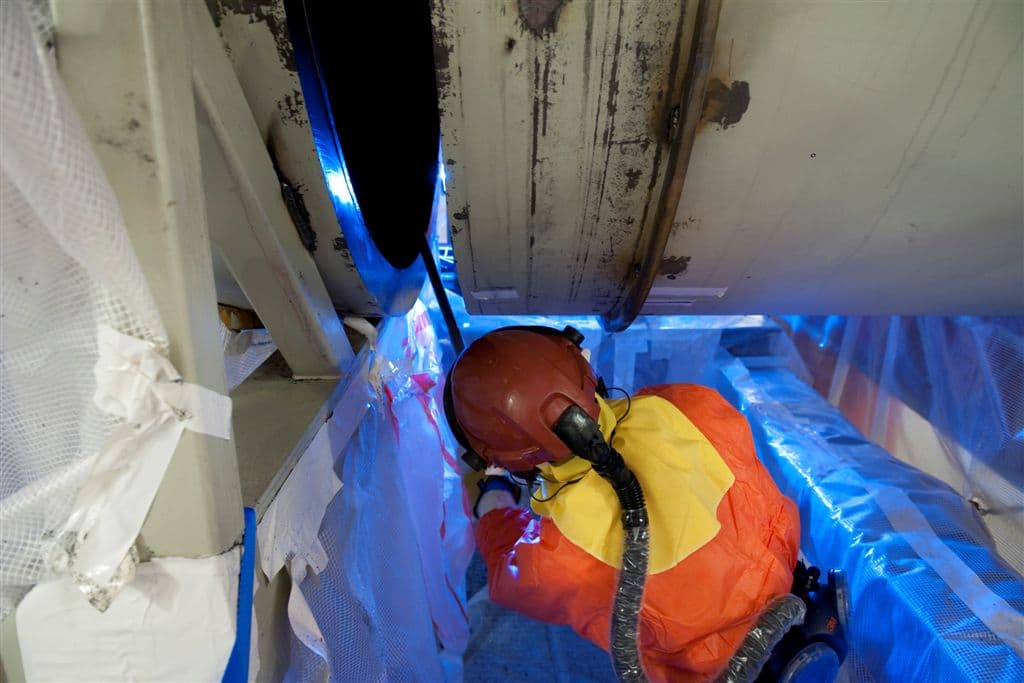

- Dismantling of 6 heat exchangers, each located in separate chambers

- Contaminated tube bundles inside the heat exchangers

- Access to the chambers only through a normal door

- No crane in the chambers for assembly and removal of the cut components

- Wire sawing not optimal due to the undefined cutting edge of the wire, contamination carryover, and risk of wire clamping when cutting through the tube bundles

solution

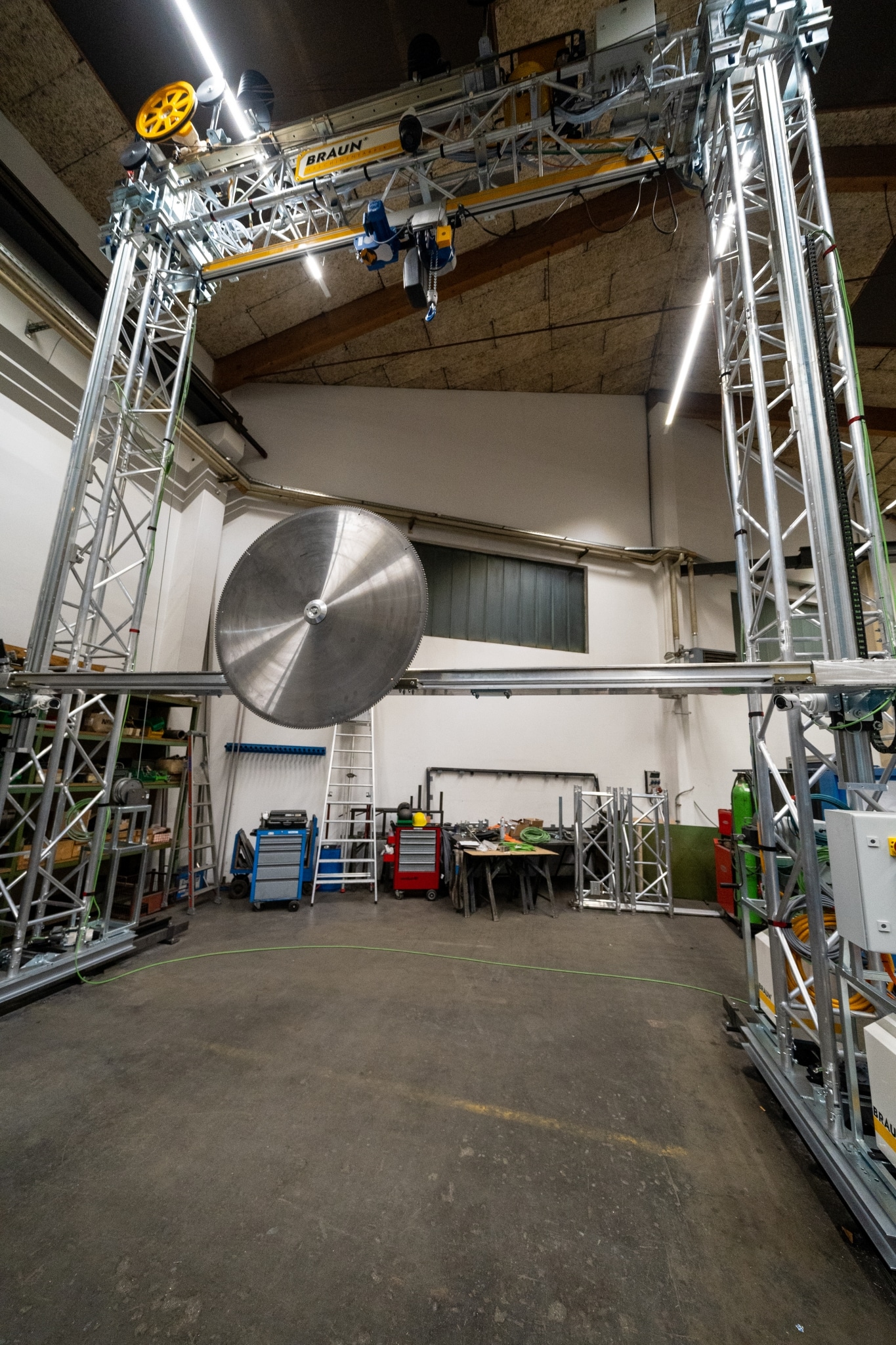

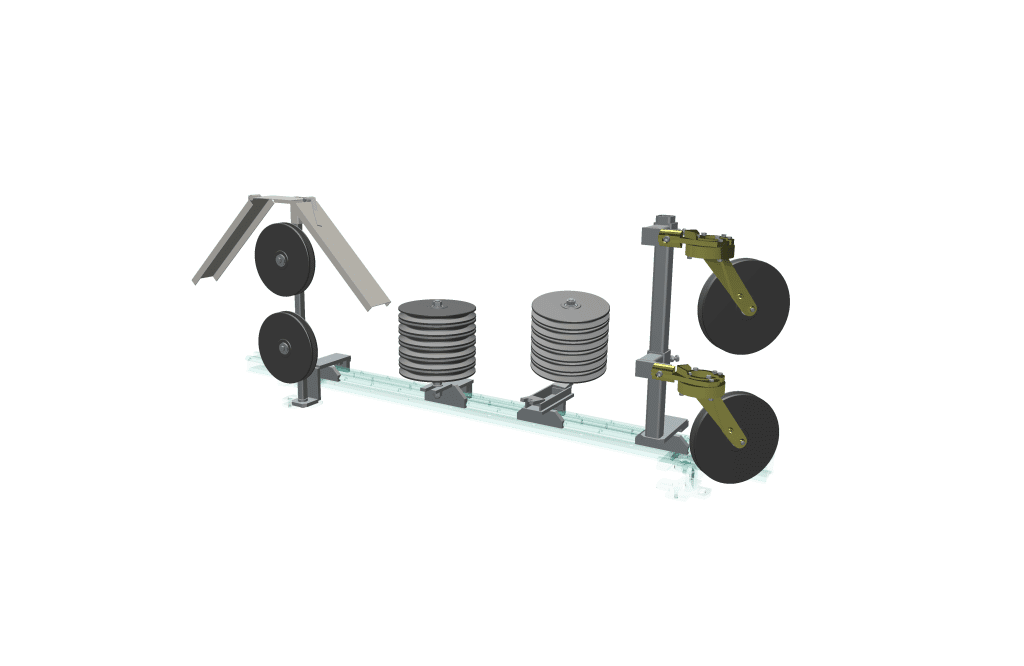

Modular construction and integrated gantry crane

Easy transport (through the door) due to the completely modular structure. The whole machine can be disassembled into small parts (not heavier than 40kg and not longer than 2.5m) and consequently adapted to different object sizes. A gantry crane integrated in the system allows the assembly in the chamber and the removal of the cut parts. Since the tubes are internally contaminated, the system had to be largely automated and remote-controlled via cameras.

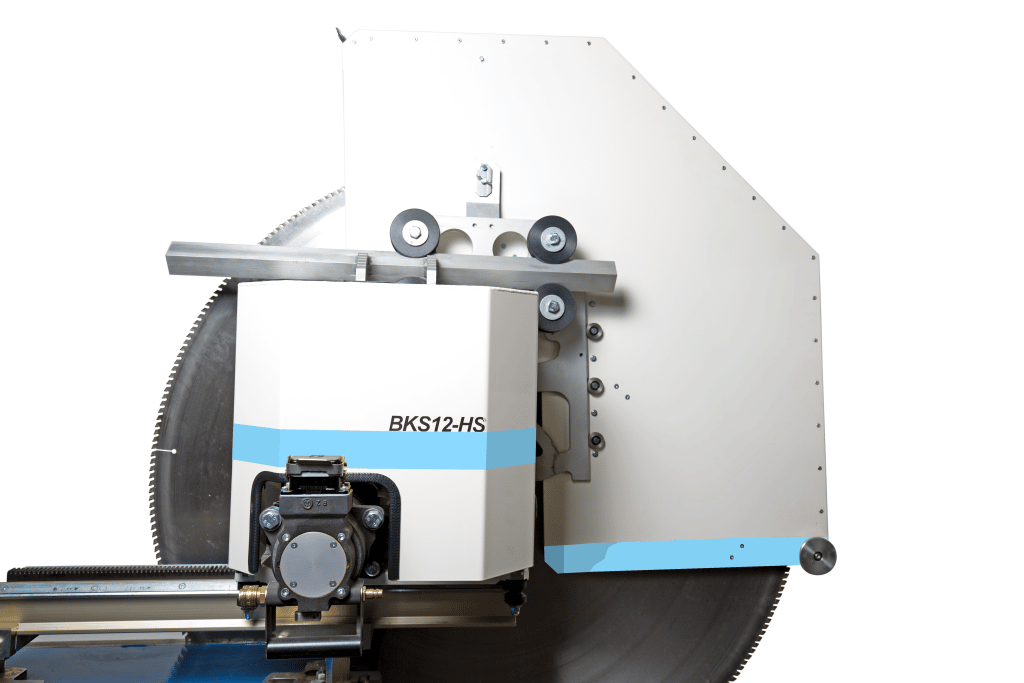

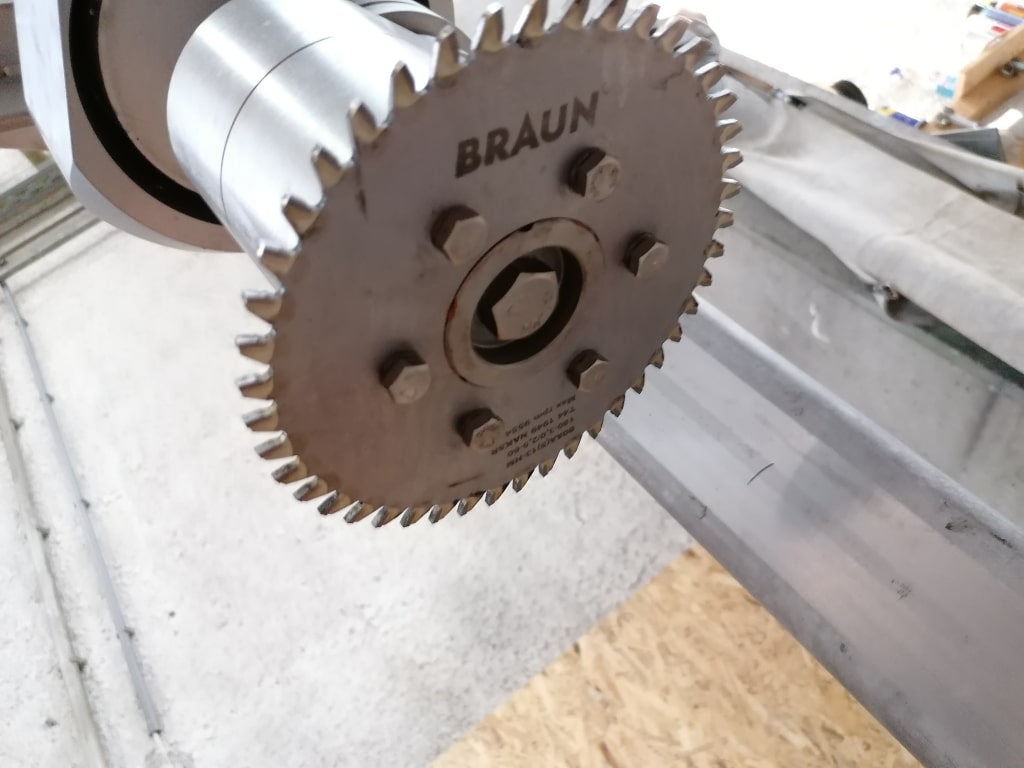

Integrated cold cutting saw

The patented BRAUN cold cutting saw is up to 10 times more efficient than a wire saw when cutting steel. Only in the case that the diameter of the saw blade is too small to cut through certain components, wire sawing is necessary.