Projects

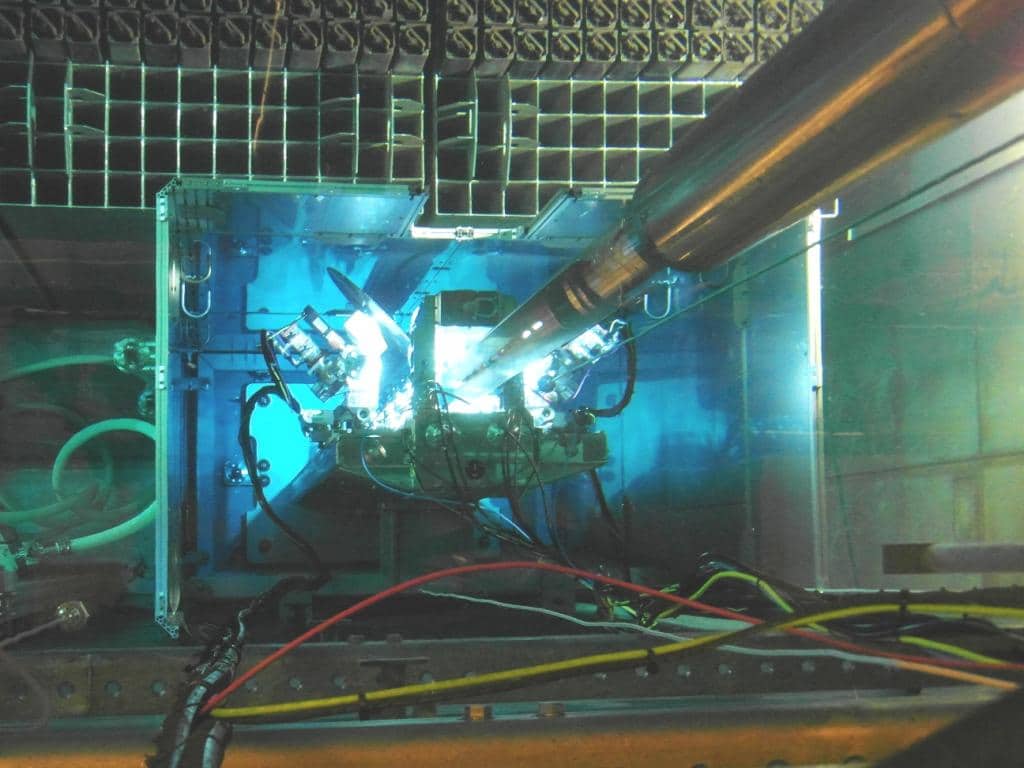

Germany – Nuclear Power Plant Mülheim-Kärlich

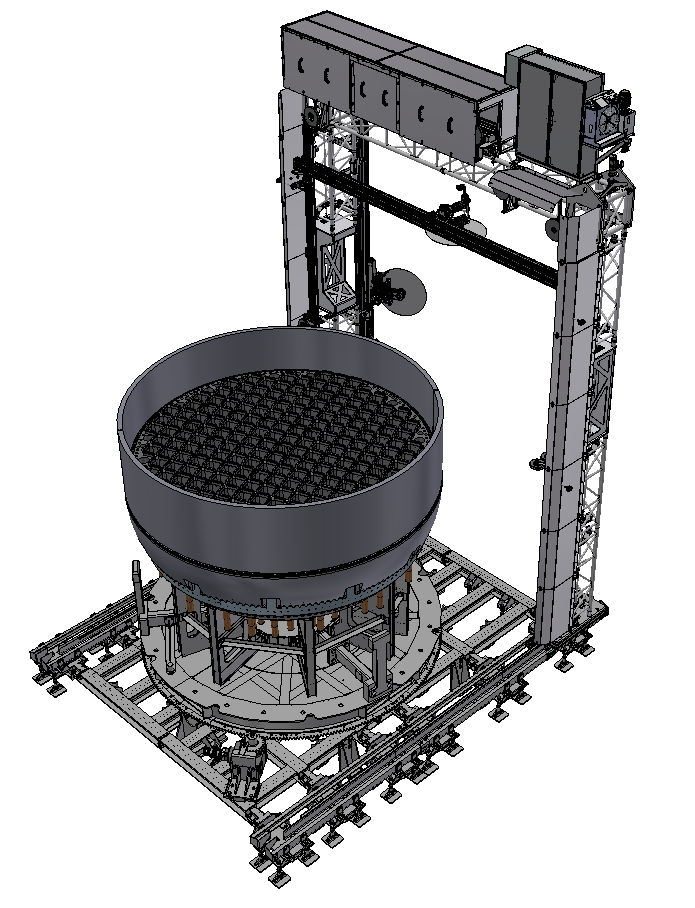

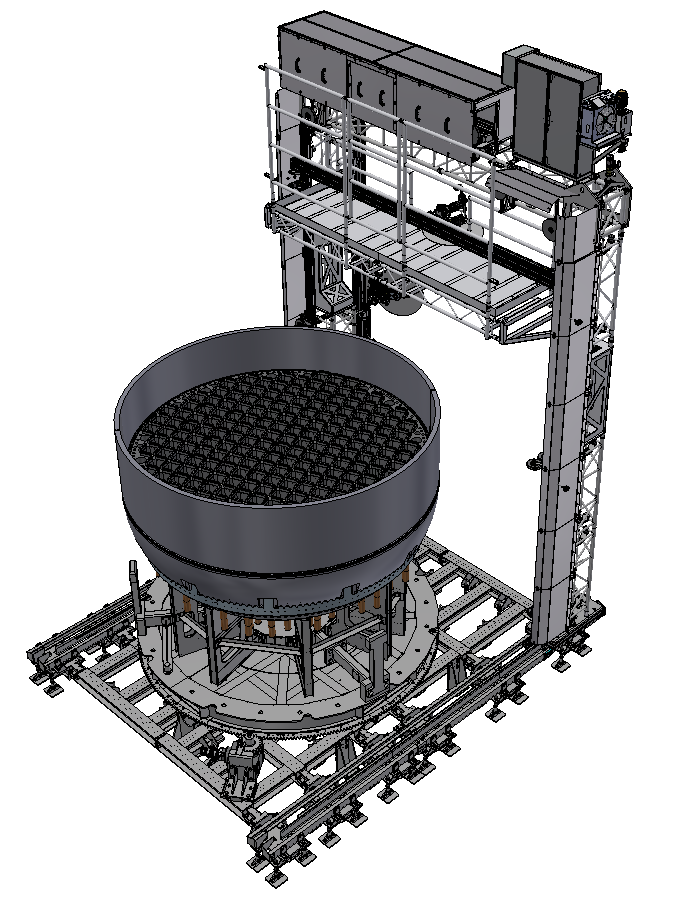

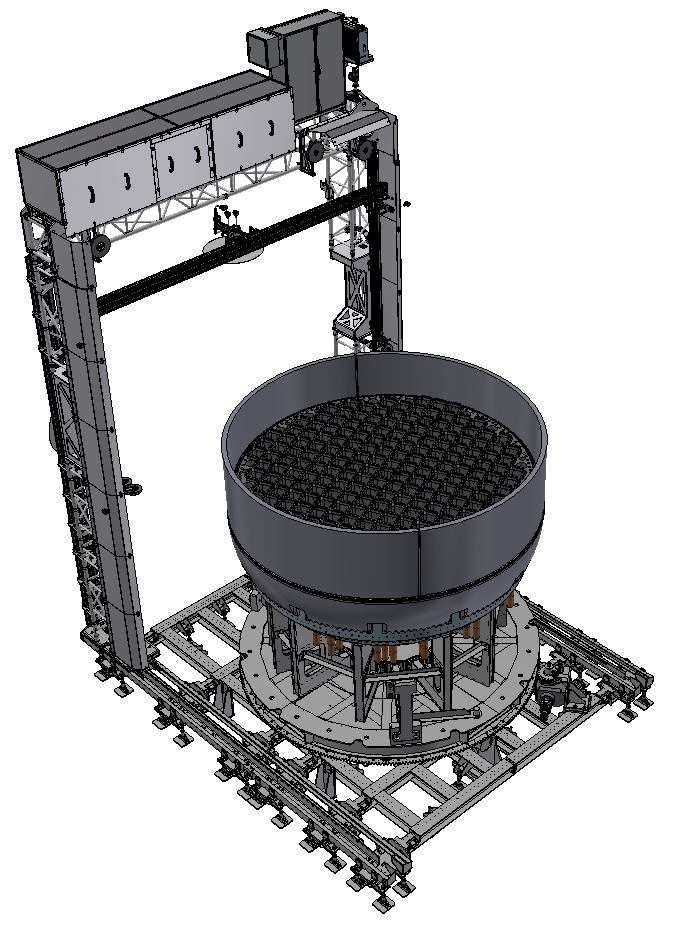

Development and production of an underwater bridge saw incl. substructure with 360° rotary table for dismantling reactor internals.

task and problem definition

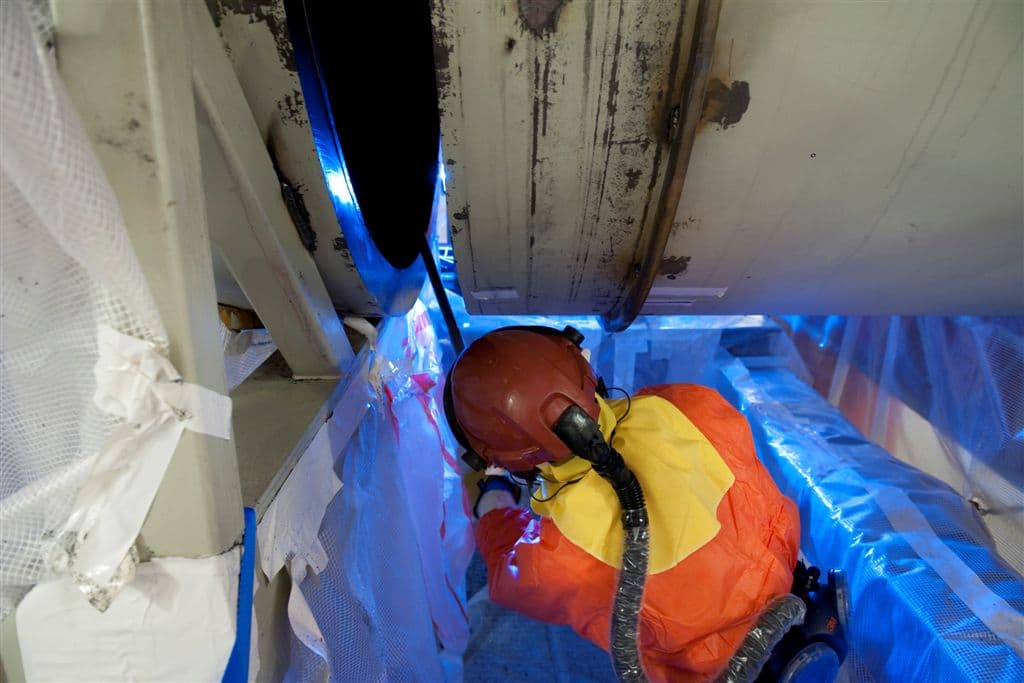

Deployment in the hot zone of the Mülheim-Kärlich nuclear power plant

- Dismantling the upper core grid

- Dismantling the lower support structure of the lower core grid

- Mechanical dismantling

- Under water dismantling

- Tight space conditions (deployment in the storage pool)

- Decontamination capability as good as possible

- Lightweight construction

- Modular construction

- Preliminary examination documents

solution

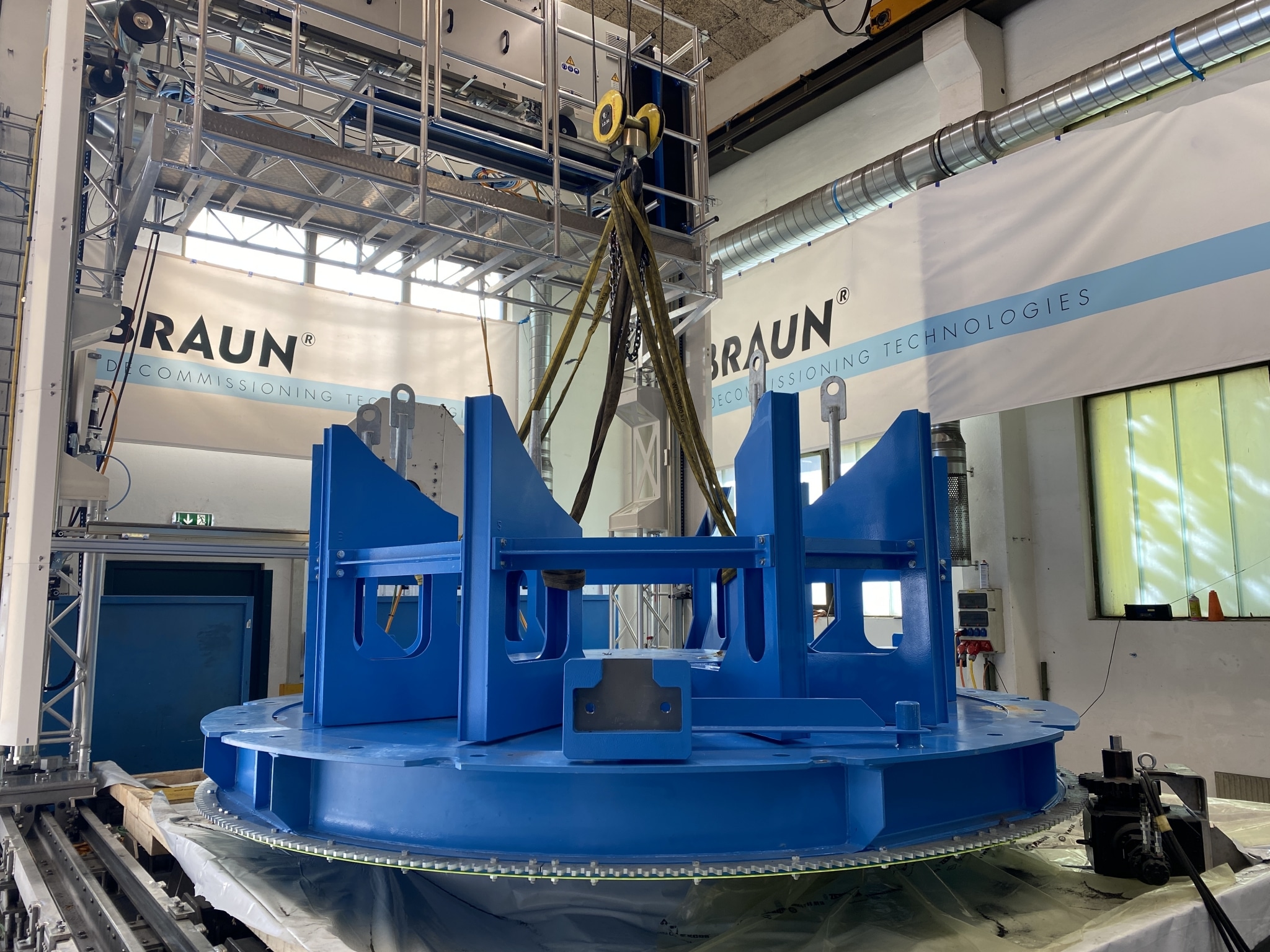

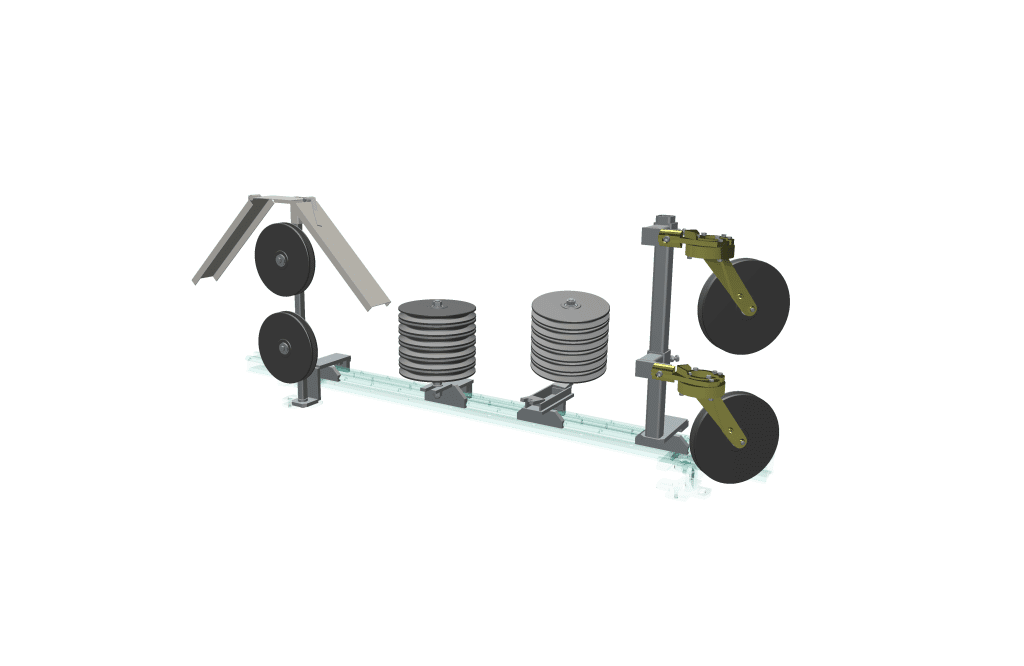

Bridge and rotary table

The parts to be cut are rotated on the 360° rotary table, which allows the cutting process to be performed from any angle. The bridge structure travels one-dimensionally over the parts. Cavities have been avoided as far as technically possible to allow easy decontamination.

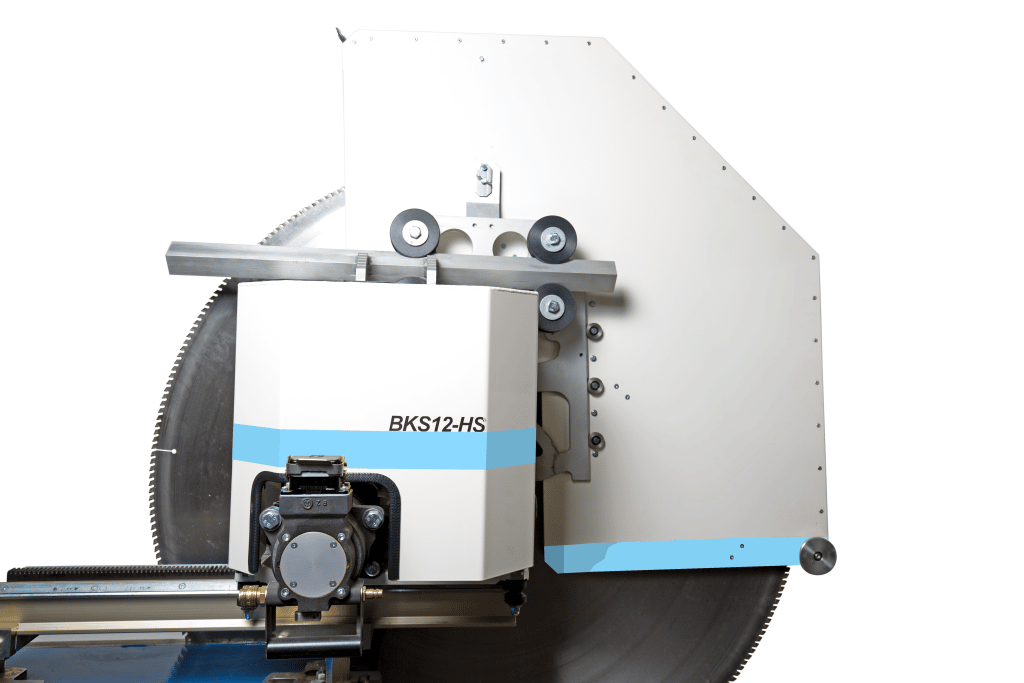

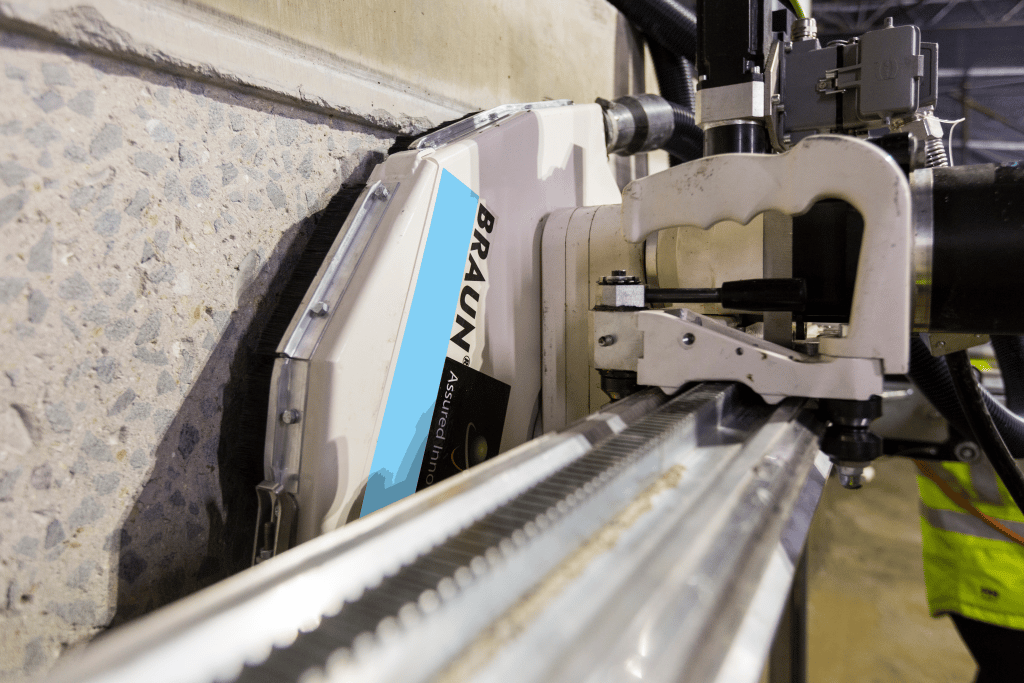

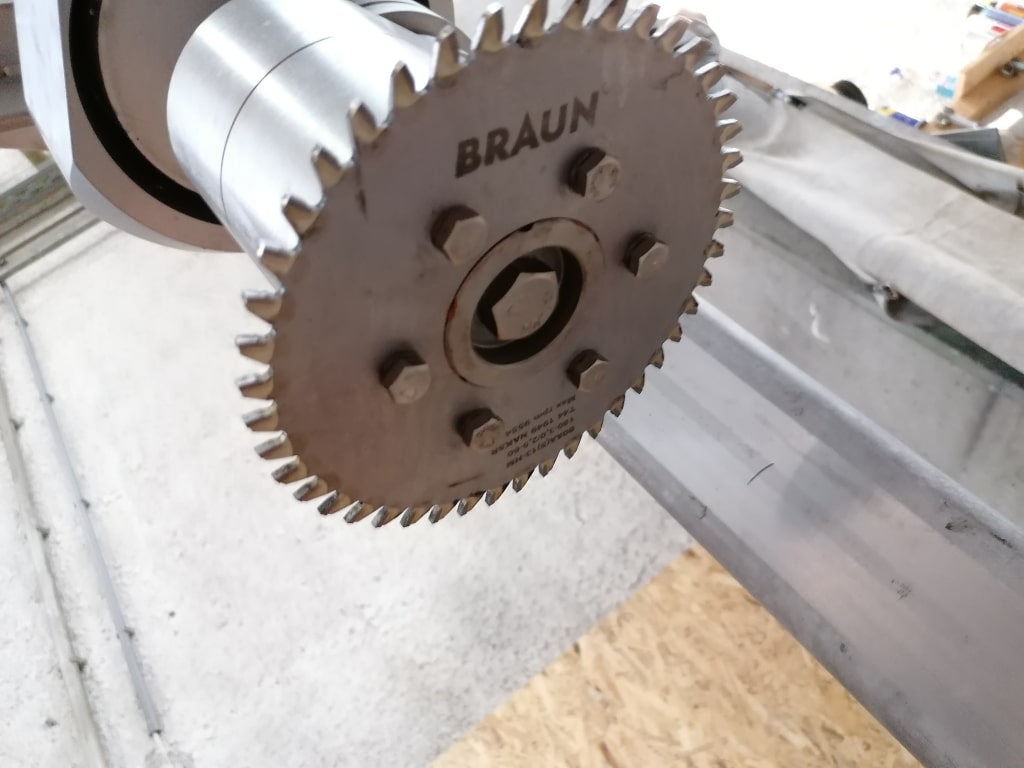

Cold cutting saws

Primarily, the cutting is to be carried out with the BRAUN cold cutting saws, since significantly better cutting times can be achieved than with the wire saw due to the defined cutting edge. Furthermore, the saw blades produce much larger chips, which are easier to control. Two cold cutting saws are included in the bridge system (horizontal and vertical).

Wire saw

For cuts where the diameter of the saw blades is not sufficient, the BRAUN wire saw is used. The cooling of the motor is ensured here with the BRAUN cooling system (closed cooling circuit).