Decommissioning Technologies

Decommissioning of nuclear facilities

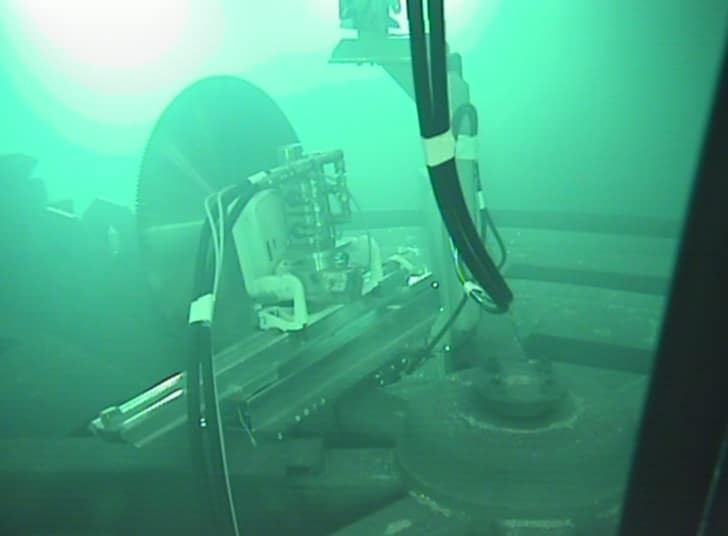

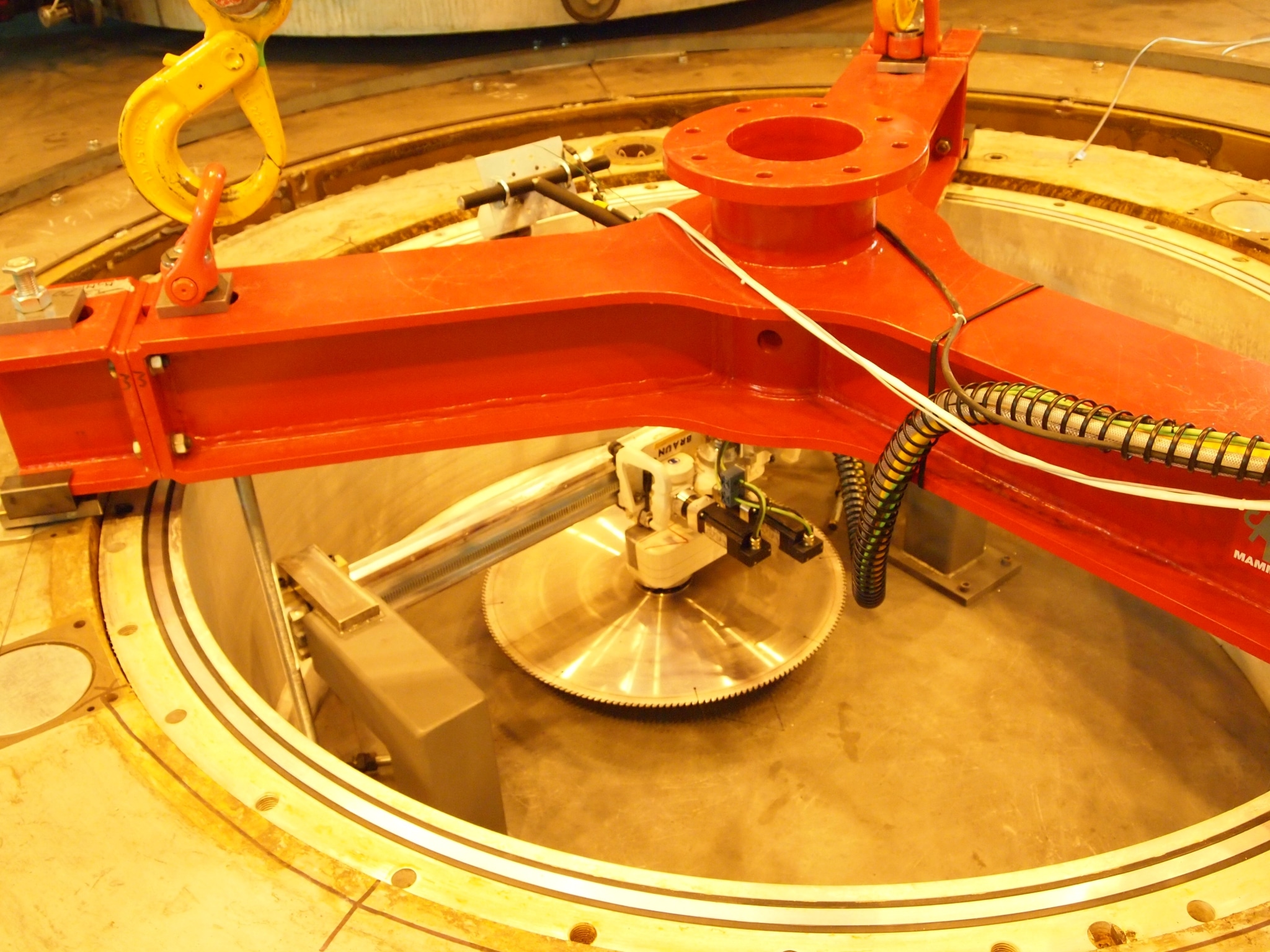

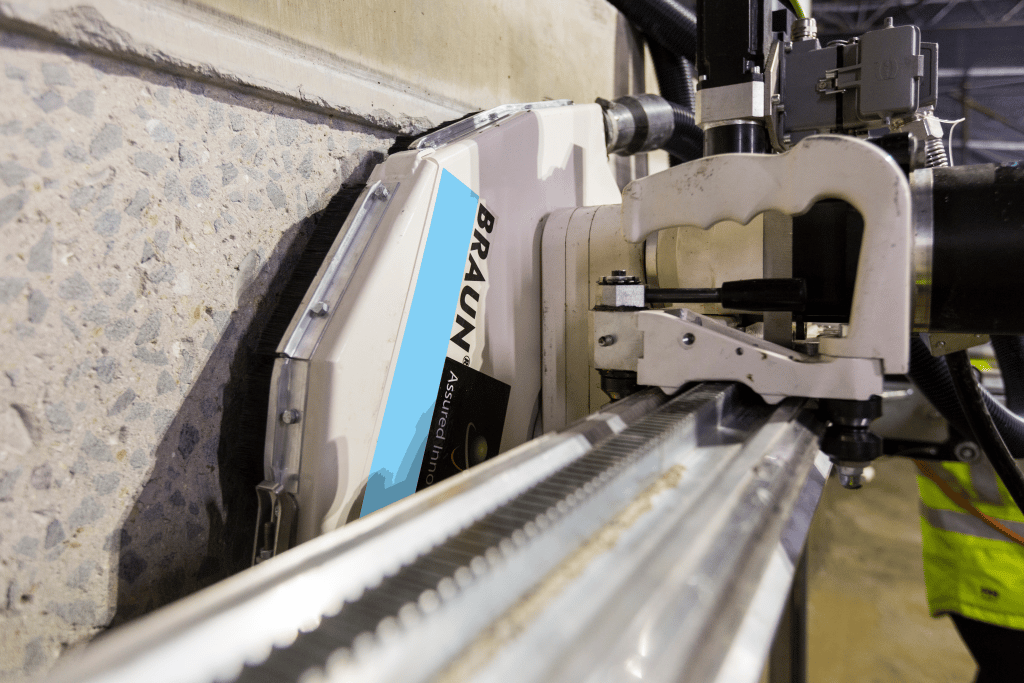

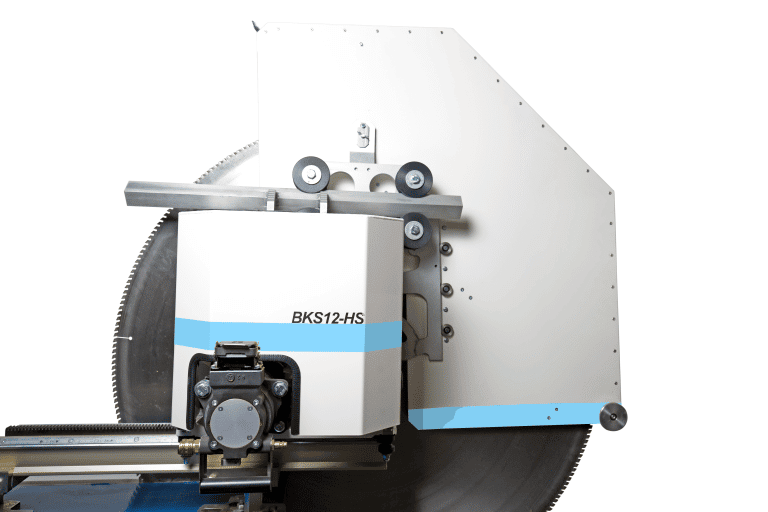

Cold Cutting Saw

The patented system for cold cutting of steel structures

The optionally electrically or hydraulically operated saw is deployed for extreme challenges. The mobile machine can easily be used up to 20 meters under water and can also be operated dry, without any cooling of the tool. The cold cutting process and innovative fastening options enable safe sawing of high-alloy metals, copper, lead as well as composite materials of various types. Remote operation as well as automatic fastening allow cuts in confined spaces, on non-transportable components and at great heights. The modular assembling and the cutting depth of up to 535 millimeters, with a weight of only 40 kilograms, enable a wide range of applications with high work safety.

Advantages: spark-free cold cutting process, high cutting performance compared to wire saw, light and mobile, can be operated by remote control, suitable for underwater applications, dry cutting possible, cuts high-alloy steels, copper, lead, cast materials and much more.

Technical data

Saw blade diametermax. 1200 mm

Cutting depthmax. 535 mm

Swivel range360°

Feed & deliveryelectric

Tool driveelectric / hydraulic

Tool drive powermax. 26 kW

Protection classIP68

Weight saw head25,8 kg / 33 kg

Weight HF-motor14 kg

Hydraulic motor5,5 kg

Accessories

- Camera system

- Blade guard with spray nozzles for blade cooling

- Specially coated saw blades

- Guide tracks

- Track feet angle cut

- Track connectors

- Different track fastening options such as vacuum plates, magnetic feet or hydraulic track clamps

Saw blades

The tool specially developed for the cold cutting saw

In the course of many years of research, these saw blades were specially developed for the BRAUN cold cutting saw to enable the highest cutting performance. The machine and the tool have been mutually adapted to each other, resulting in an optimal interaction. The saw blades can be resharpened several times, a mobile sharpening machine can be purchased from BRAUN. Furthermore, the saw blades can be produced with narrow or wide toothing, and can also be coated, which significantly reduces the coefficient of friction. The coated saw blades are also patented by BRAUN Decommissioning Technologies.

Advantages: Resharpening possible up to 7 times, coated or uncoated, narrow or wide toothing, variable diameters up to 1200 mm possible.

Download

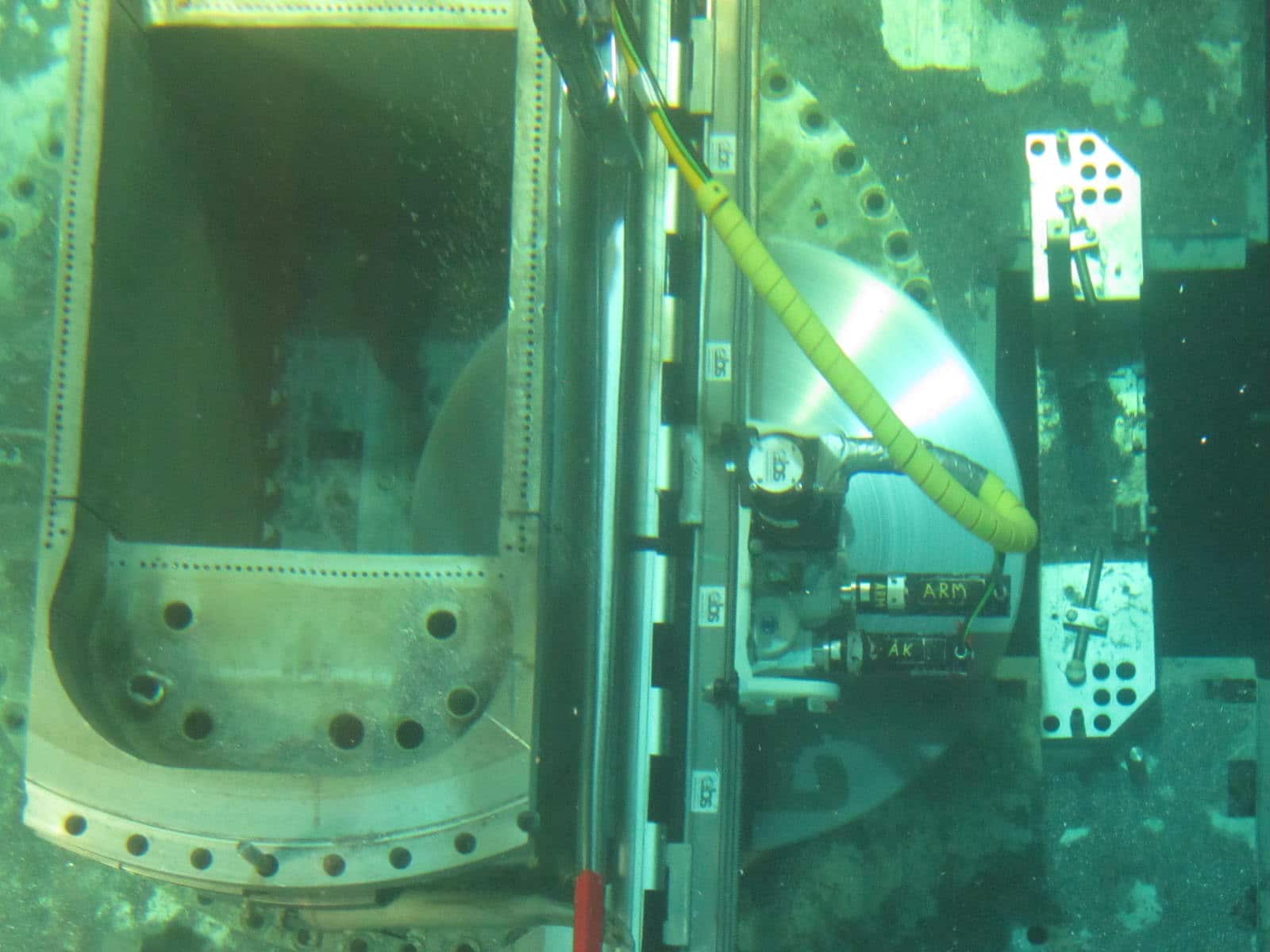

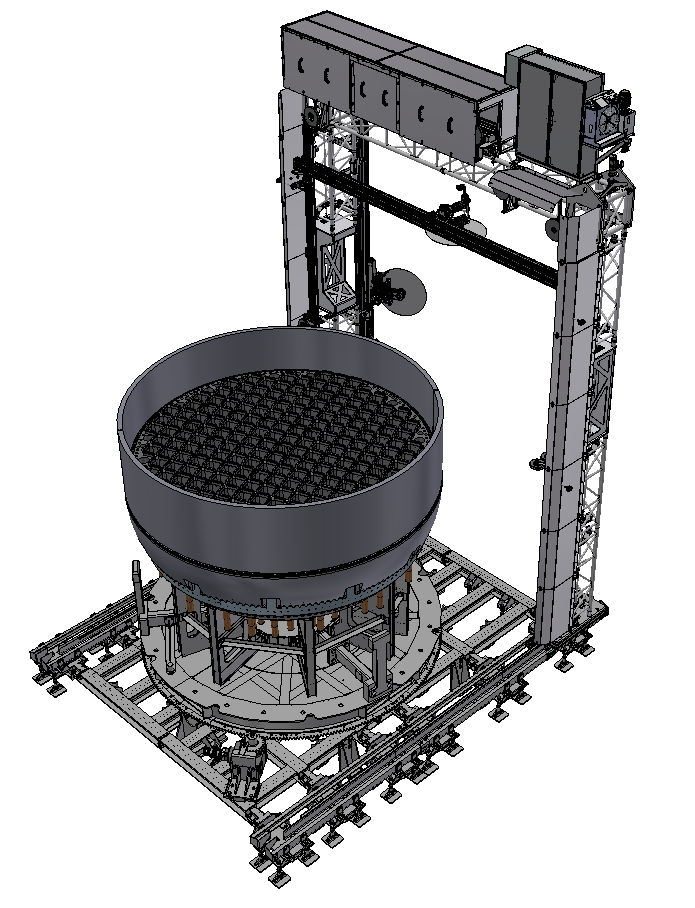

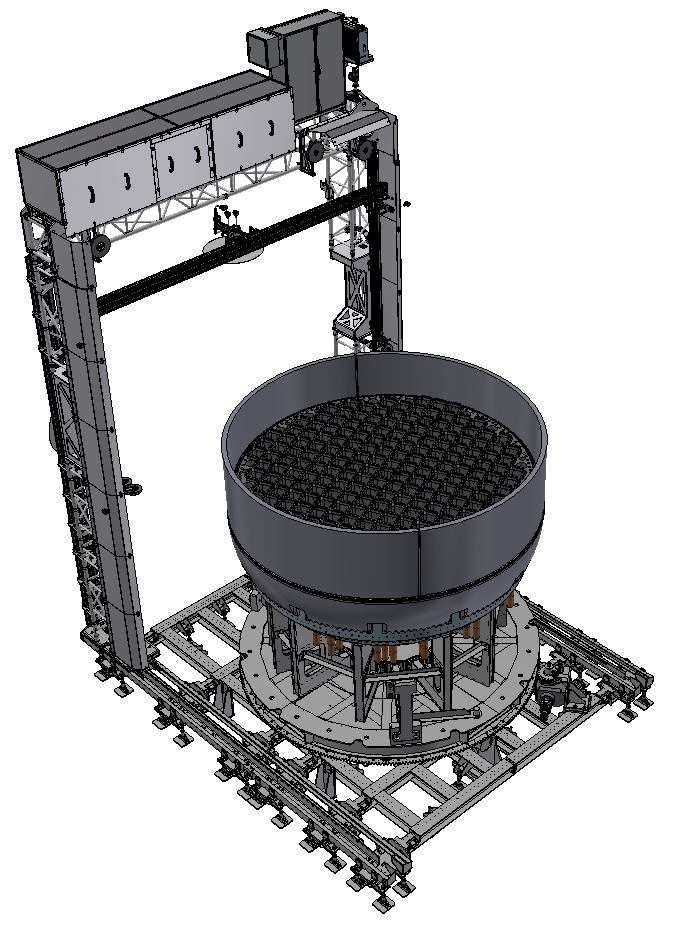

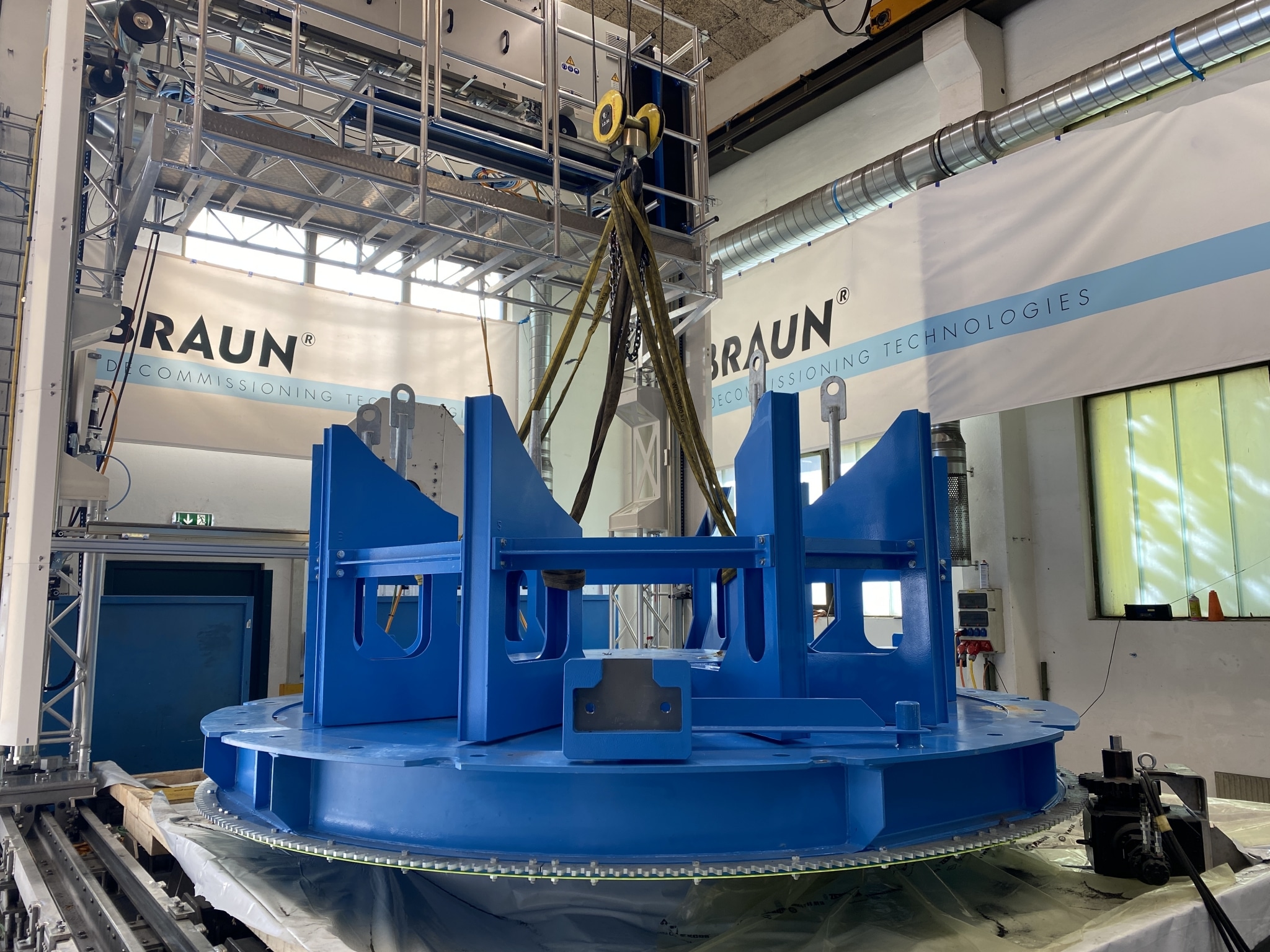

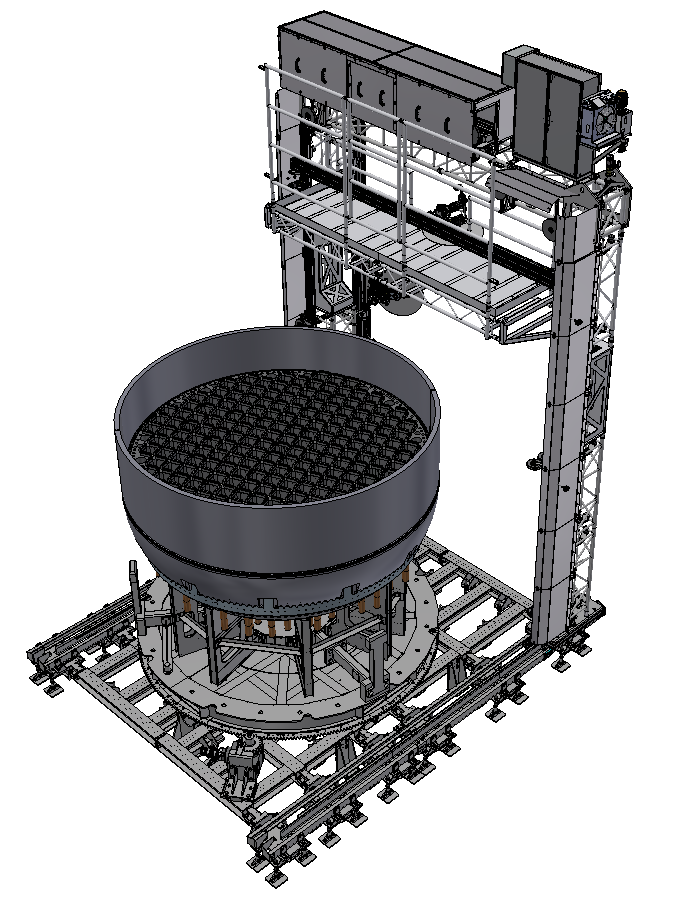

Bridge saw

The universal post-cutting station

The bridge structure was designed in a lightweight and modular way, so that weight is saved and the system can be adapted to components of different sizes. The bridge saw combines several cutting technologies (horizontal and vertical) and travels one-dimensionally on a rail system above the parts to be cut, such as reactor internals. In addition, the system can be equipped with a 360° rotary table so that the cutting process can be performed from any angle. Mechanical dismantling takes place under or above water. The BRAUN bridge saw is used as a post-cutting station e.g. in the German nuclear power plant Mülheim-Kärlich.

Advantages: variety of dismantling options under or above water, modular design, lightweight construction, good decontamination capability, purely mechanical dismantling.

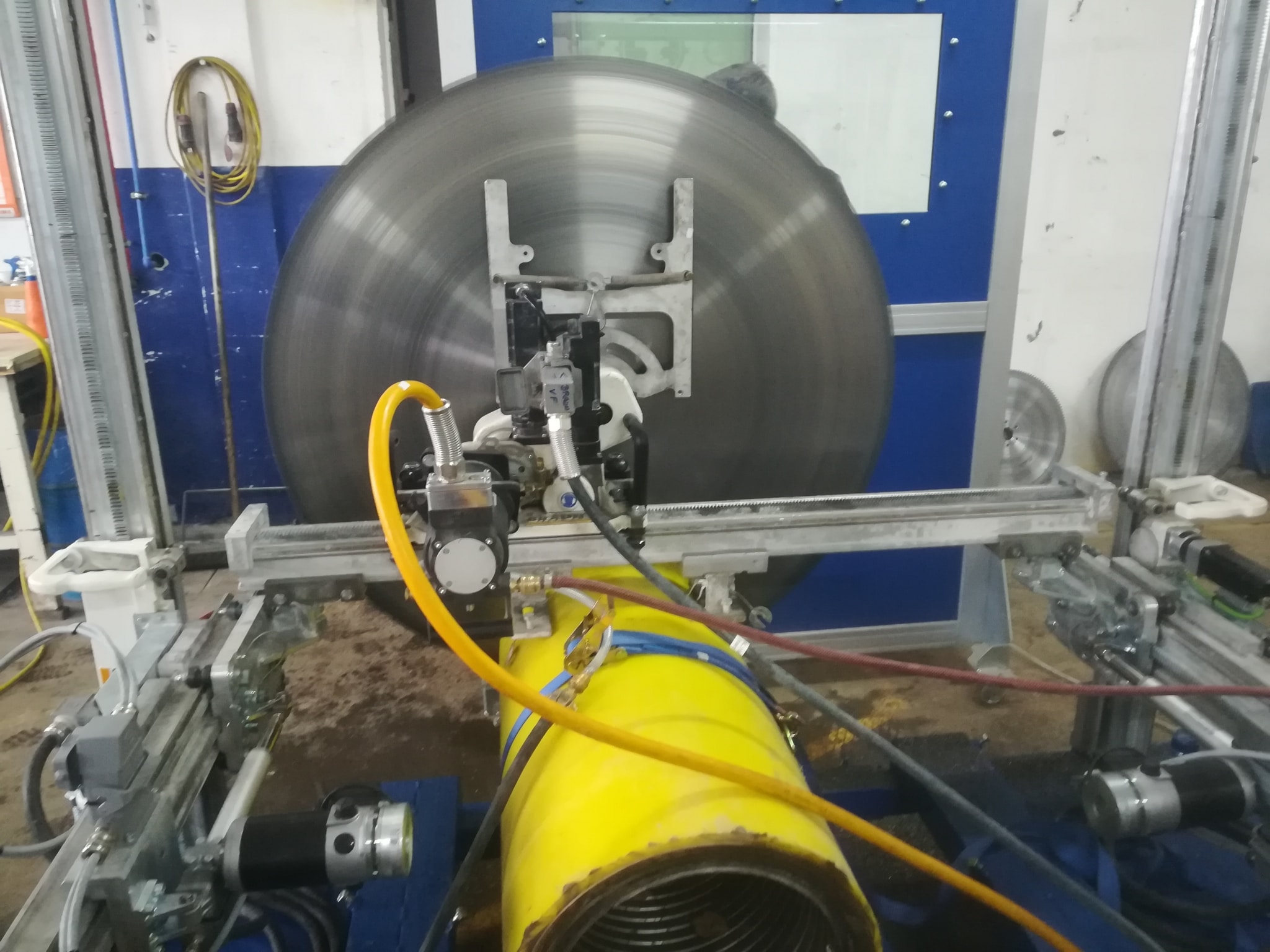

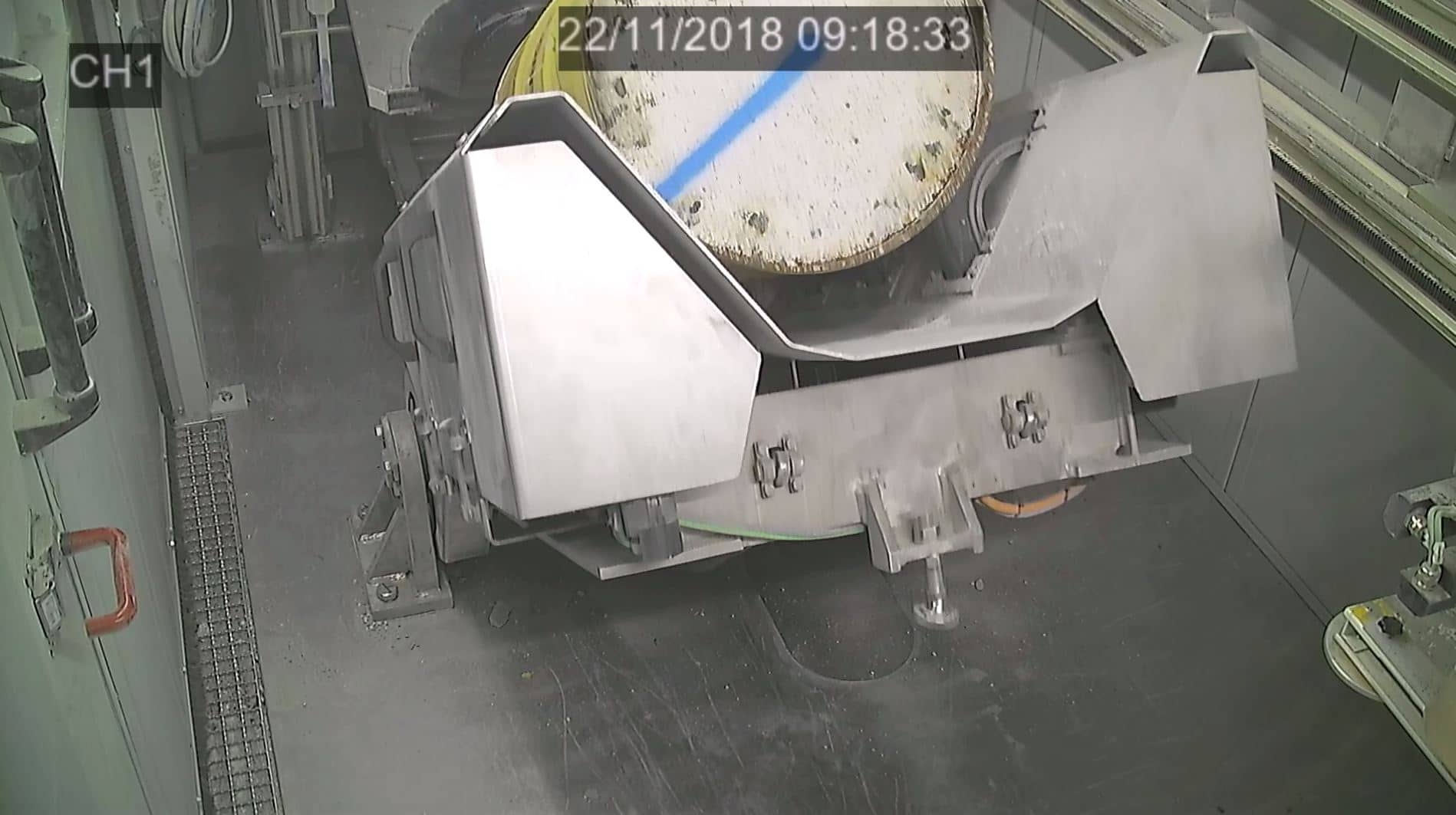

Drum Dismantling Machine

The patented system for the dismantling of drums with radioactive waste

This stationary, remote-controlled system was developed for the reconditioning and post-conditioning of homogeneously and inhomogeneously cemented, radioactive waste packages. Due to the complete dismantling, the contents can be analyzed and documented in detail. The contaminated material is separated from the non-contaminated, which allows the volume of radioactive waste to be halved. Furthermore, the diameter of the concrete matrix is reduced to allow insertion into the new drums with fiberglass inner liners. The dismantling process is dry, so no secondary waste is generated. The BRAUN Drum Dismantling Machine has been in operation at the Seibersdorf interim storage facility in Austria since 2018.

Advantages: variety of dismantling possibilities without secondary waste from a safe distance, volume reduction of radioactive waste by up to 50%.

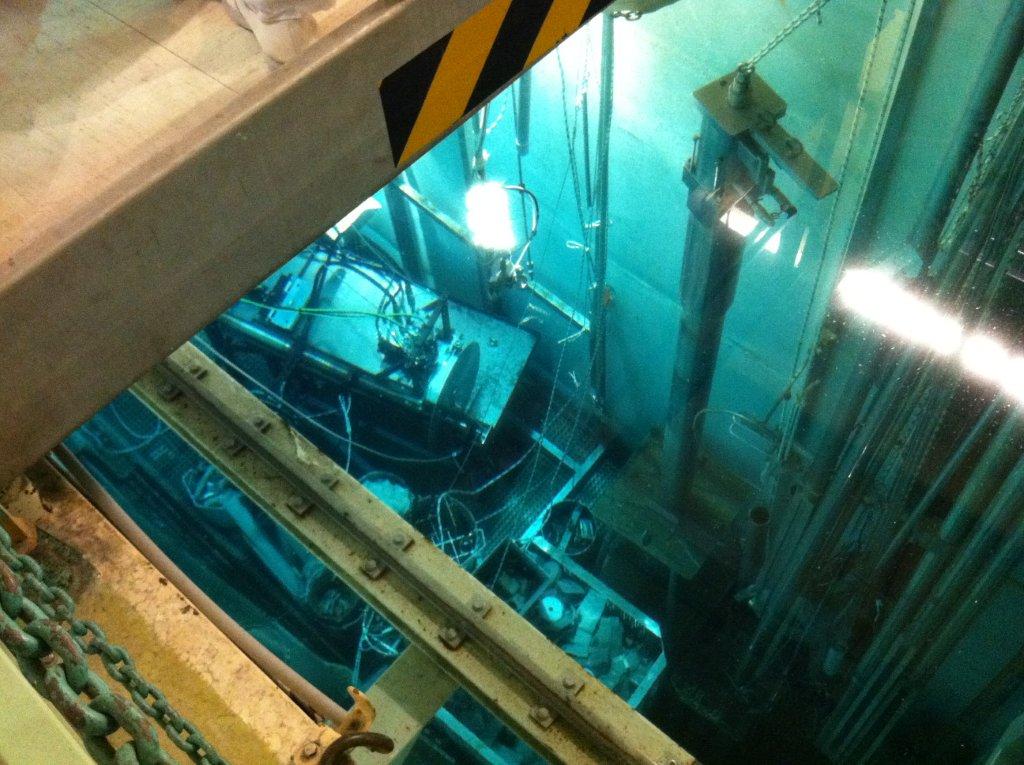

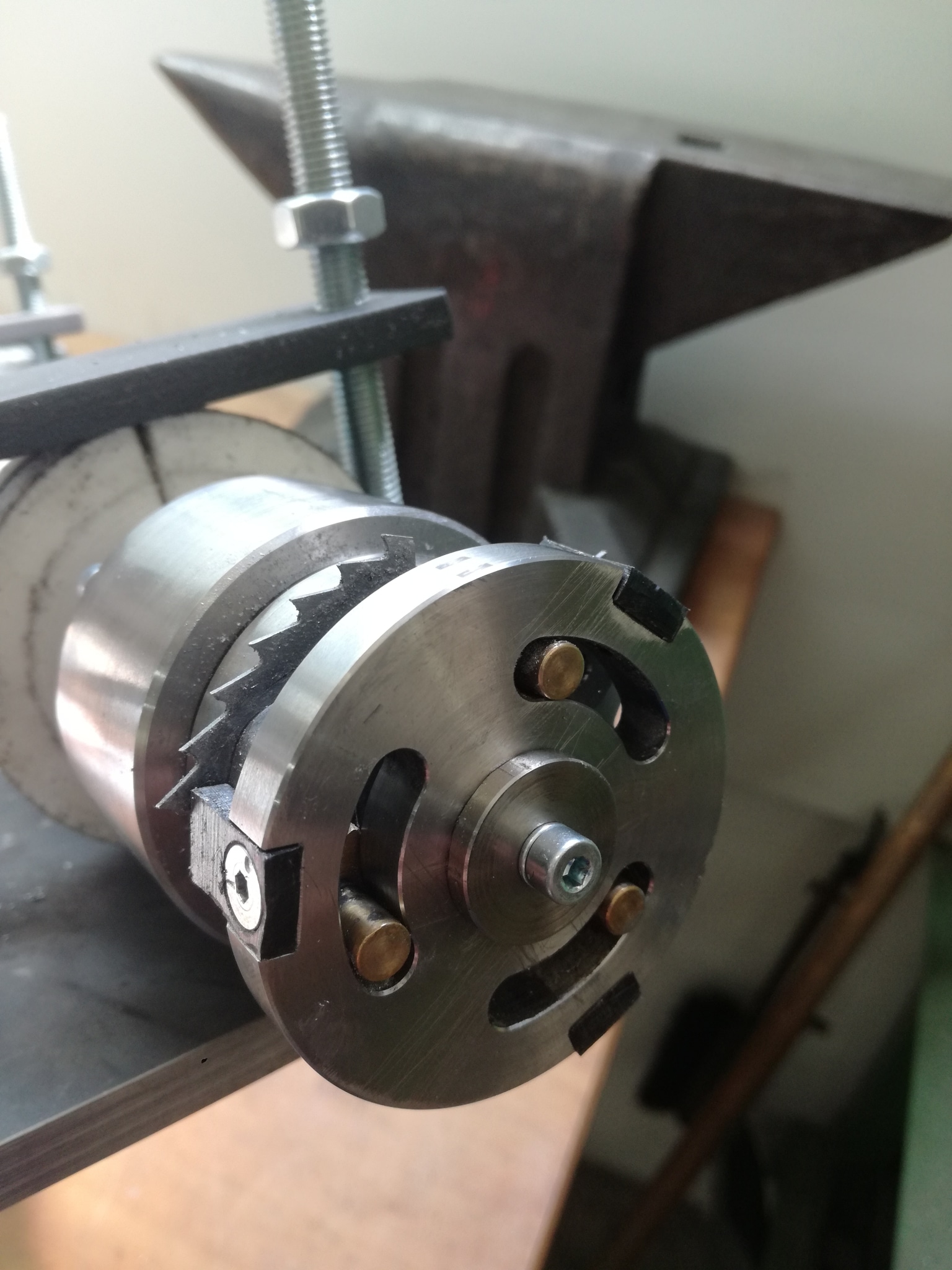

Internal Pipe Cutter

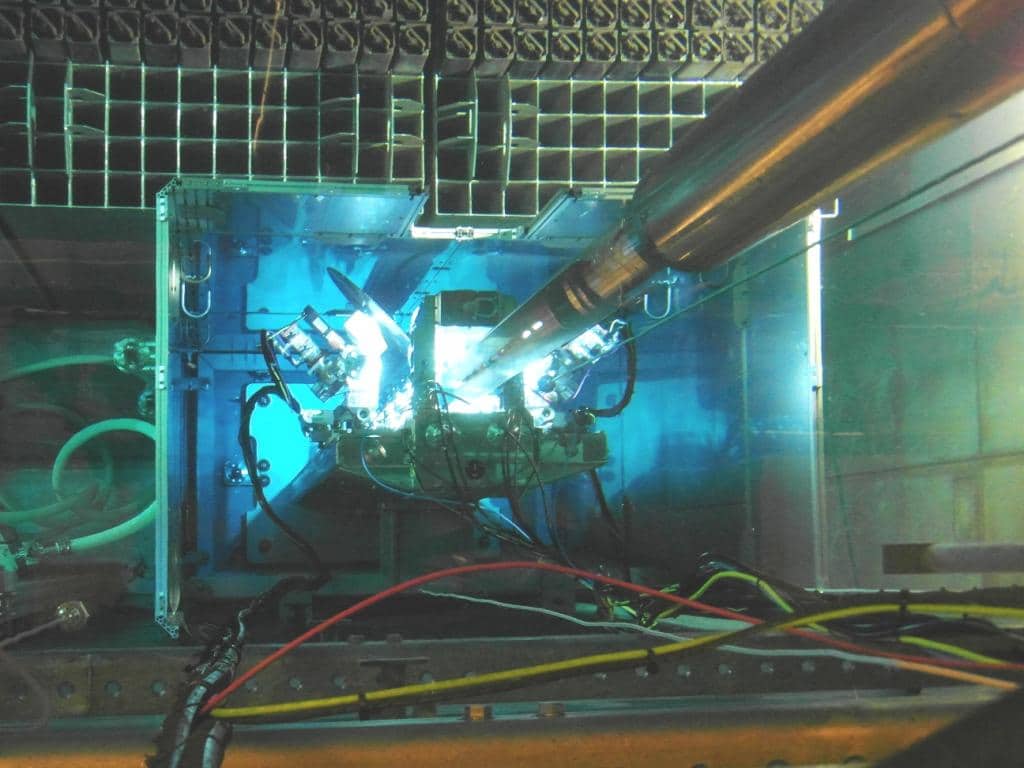

Internal cutting of pipes under and above water

The BRAUN Internal Pipe Cutter was developed for the dismantling of control rod guide insert supports and can be used both under and above water. The small saw blades are available in different diameters and produce large chips so that they can be collected and extracted well. In the event that a saw blade clamp occurs in the stainless steel pipes, there is an emergency recovery flange that allows the machine to be safely recovered. Furthermore, the internal pipe cutter is also used for the removal of the dismantled pipe parts. The BRAUN Internal Pipe Cutter is used, for example, in the German nuclear power plants Philippsburg or Biblis.

Advantages: Dismantling from the inside under or above water, mechanical dismantling by spark-free cold cutting process, high cutting performance, remote control, emergency recovery possible.

Wall Saw Carrier

double-sided cutting

For a complex project in Canada, a contaminated wall had to be cut from both sides. A special carrier was designed and manufactured for this purpose, which travels on a track system attached to the floor. Two BRAUN wall saws are mounted on this carrier. One saw is attached directly to the carrier, while the second saw is positioned using a pivoting track frame and vacuum plates. A customer-specific control unit was programmed for this project.

Advantages: double-sided cutting, mechanical cutting, dry cutting with coated saw blades.

Remote Core Drilling System

remote-controlled core drilling

The BRAUN Core Drilling System was developed for a nuclear decommissioning project in Canada. The BRAUN Wall Shaver is used as the basis. Thanks to the modular design, it can be quickly converted in a few steps. Operation is remote-controlled with a universal control system that can be used for many other BRAUN machines.

Advantages: quick conversion from Wall Shaver to Core Drilling System and vice versa, remote-controlled with a universal control unit.

Centrifugal Cutter

Cutting without feed drive

For a complex project, contaminated aluminum tubes of particularly small diameter had to be dismantled from the inside. An additional difficulty was that the tube diameter was not always the same, but varied. For this challenging project, the BRAUN Centrifugal Cutter was developed after several years of intensive research. The extraordinary feature of the system is that the feed of the saw blades is generated purely by the natural law of centrifugal force. This small but very special machine thus enables internal cutting of aluminum tubes, and can be used for tasks where cutting from the outside is not possible.

Advantages: Internal dismantling, mechanical dismantling, feed of saw blades is generated purely by centrifugal force.