Customized Solutions

BRAUN Customized Solutions

In-house engineering and manufacturing can draw on many years of experience in special designs. We often combine our proven product technologies with new designs. The commissioning of the customized machines is carried out by us on site or in our factory.

Sawing and drilling modules for robots

For the machining of prefabricated brick walls

Four different machining modules, including interface for coupling to a robot arm, were developed for this project. The first two modules are wall sawing modules, one with a saw blade diameter of 900 mm and the other carries a saw blade package with a diameter of 600 mm. The third machining module combines a drilling unit with another saw blade package, with a smaller diameter of 300 mm. The fourth module carries a chain saw. The robot arm selects between the different modules depending on which machining step is currently required. The cutting process and tool change are fully automatic.

The tool modules can be combined individually, depending on requirements.

Saw for precast concrete

Stationary saw with combined cutting unit

This saw, based on a bridge design, was developed for cutting precast concrete elements as well as reinforcing cages.

The cutting unit of the machine combines two different cutting tools, a cut-off wheel and a diamond saw blade. Due to this mixed processing, tool costs are greatly minimized. The diameter of the cut-off wheel and the diamond saw blade is 700 mm. The drive power for both tools is 11 kW.

Saw for aerated concrete

Stationary horizontal cutting saw

The sawing unit is mounted on a shaped tube bridge structure and a double-guided slide. The saw blade, with a diameter of 1500 mm, penetrates horizontally into the aerated concrete package. The horizontal movement is performed by an encapsulated servo drive. A BRAUN cooling unit is used to cool the tool drive. The cooling water and cables are routed in an energy chain. The control takes place at a touch panel, which is built into the control cabinet. A suction hood including connection point as well as a line laser for optical positioning are integrated in the system. The tool drive is 18 kW.

Pipe cutting machine

Dismantling from the inside on the basis of a BRAUN drill stand

This machine was designed for internal cutting of pipes, with a diameter of 3 meters.

The engineering and design team focused here on an efficient and cost-effective solution for the end user based on series parts from the modular BRAUN product portfolio, with the BRAUN drill rig acting in a central position.

The feed is performed manually by means of a drill rig stroke. Upon customer’s request, the swivel drive was also designed manually, an electric or hydraulic version can also be manufactured as an option.

The pipe cutting machine can also be used, for example, to cut expansion joints in tunnels.

Brick shaving machine

Milling machine for brick mantle blocks

The BRAUN brick shaving machine was developed for milling screw recesses in the shape of a triangle for chimney bricks. The machine was assembled almost entirely from existing series parts of the modular BRAUN product portfolio. The milling head consists of the titan wall saw head and a saw blade package as milling tool. A protective hood was custom-made. The height adjustment of the milling head is controlled by a hand wheel, the stroke path is approx. 1200 mm. A track mounted transversely to the lifting frame allows the shaving head to travel approx. 600 mm. The bricks are placed on a rotary table. The machine is controlled by a hand-panel with joystick, which allows to move within a radius of 10 meters.

Since the system is modular and mobile, it can be converted at any time for other machining techniques, such as sawing or drilling.

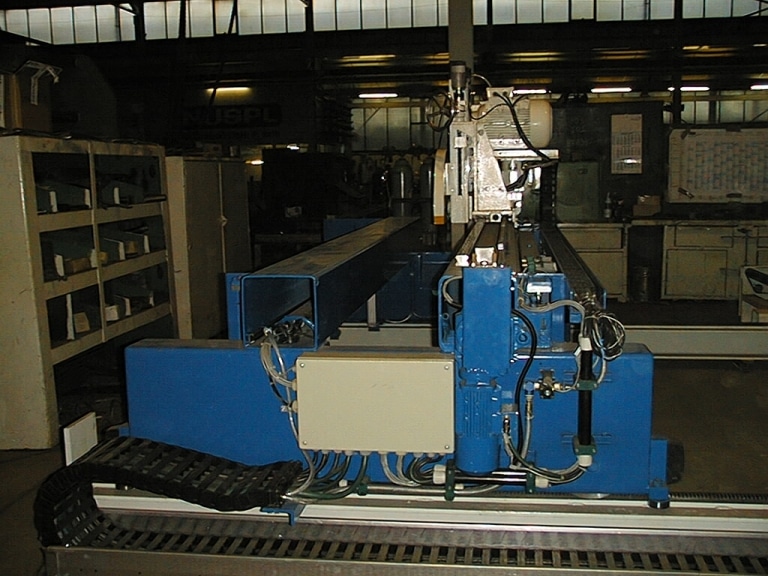

Drilling carriage

Drilling carriage on rails

This drilling carriage was developed for the drilling of rail anchors.

The carriage offers the possibility of drilling up to 8 holes simultaneously.

The carriage travels on the rails to be laid, the distance between the drill holes can be varied.

The drilling process is fully automatic.

As is so often the case, also for this machine BRAUN series components were paired with newly designed parts.

Sewer drilling system

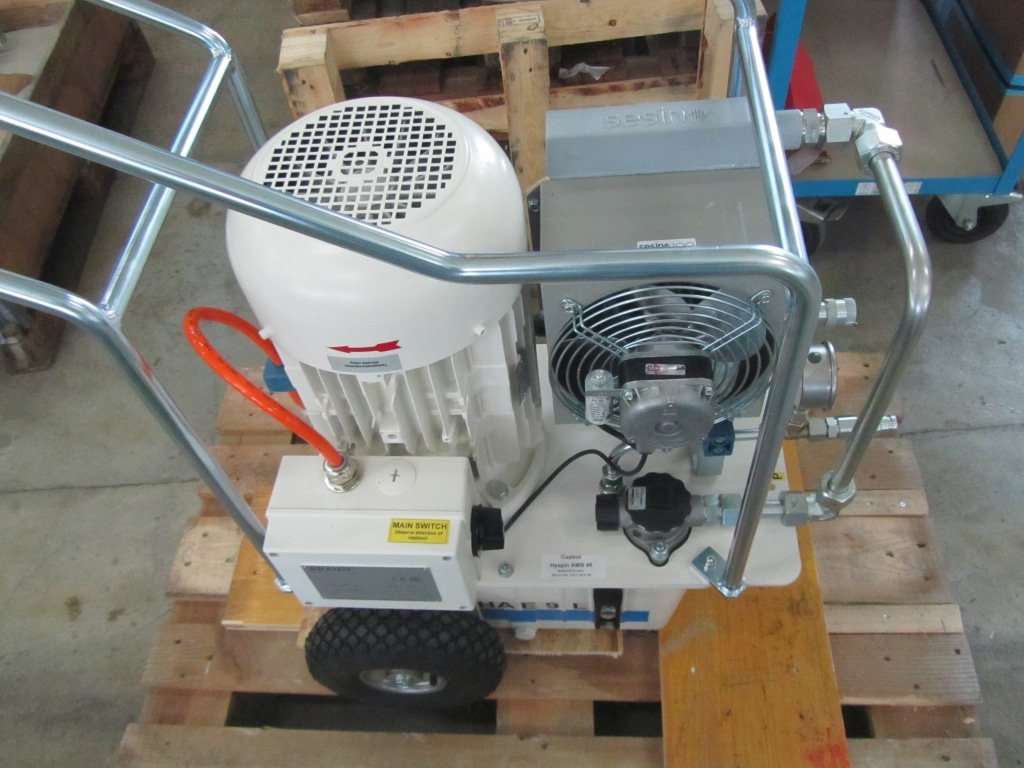

Drill rig on car

In this case, a BRAUN drill rig was coupled with a car. The vehicle is used as a hydraulic power pack and simultaneously as a mounting point for the drill rig. Furthermore, this makes the drill rig mobile. The rig is used for drilling sewer openings.

This special design provides a cost-effective as well as creative solution to a demanding drilling task.

5-fold drilling system

For multiple bores

This concept was designed for 5 simultaneous bores.

The 5-fold drilling system is also based on the BRAUN modular system, so that the entire frame can be used for cutting and other tasks in addition to drilling.

With this concept, the feed is carried out by hand. Thanks to the specially developed gearbox, a uniform drilling pressure can be performed.

On request, the feed is performed electrically.

Horizontal drilling system

For serial drilling

This special drilling system was designed to drill connection boreholes for sewer shafts in series.

The customer wanted a cost-effective solution, which was achieved by the engineering and design team making an effort to assemble the system from standard components as far as possible and to design the positioning as well as the feed only manually.

On request, the handwheels of the horizontal drilling system can be changed to electric drives and other extensions can be carried out.

Underwater drilling system

Drilling at the bottom of a river

In more complex drilling projects, it may be necessary to carry out the core drilling under water. BRAUN drilling systems can also be used for these cases. The drilling system is placed under water with cameras, so that no divers have to be deployed.

This system can be equipped with either hydraulic or electric drives.